Various Drying Energy Economy Comparison Table | |||||||

Heating Mode | Electric heating | Coal Boiler | Oil-fired Boiler | Gas Boiler | Biomass Stove | Regular Heat Pump dryer | Drytech Heat Pump Dryers |

Remove 1kg of water required heat energy | According to information provided by the relevant authority of the document, the average 1kg of water to remove heat energy required for 1.35 kw/kg, namely 4860 kj/kg | ||||||

Fuel type | Electric | Coal | Diesel | Gas | Biomass fuels | Electric | Electric |

Heat value | 3600 kj/kg | 23027 kj/kg | 33494 kj/kg | 36006 kj/kg | 17459 kj/kg | 3600 kj/kg | 3600 kj/kg |

Thermal efficiency | 95% | 30% | 85% | 85% | 90% | 350% | 400% |

Effective thermal value | 3420 kj/kg | 6906 kj/kg | 28469 kj/kg | 30605 kj/kg | 15713 kj/kg | 12600 kj/kg | 14400 kj/kg |

Fuel price | 0.1$ /kwh | 0.1$ /kg | 1.2$ /L | 0.8$ /m3 | 0.2$ /kg | 0.1$ /kwh | 0.1$ /kwh |

Fuel consumption | 1.42kwh | 0.7kg | 0.17L | 0.159m3 | 0.375kg | 0.386kwh | 0.337kwh |

Fuel consumption ($) | 1.42 | 0.7 | 1.26 | 0.795 | 0.37 | 0.39 | 0.33 |

Labor management, warehousing costs | Higher | High | High | High | Low | Low | Low |

Safety performance | Unsafe | Unsafe | Unsafe | Unsafe | Safe | Safe | Safe |

Environmental pollution | None | Very serious | More serious | More serious | Light pollution | None | None |

Life of equipment | 5-8 years | 6-9 years | 6-9 years | 6-9 years | 8-12 years | 10-15 years | 10-15 years |

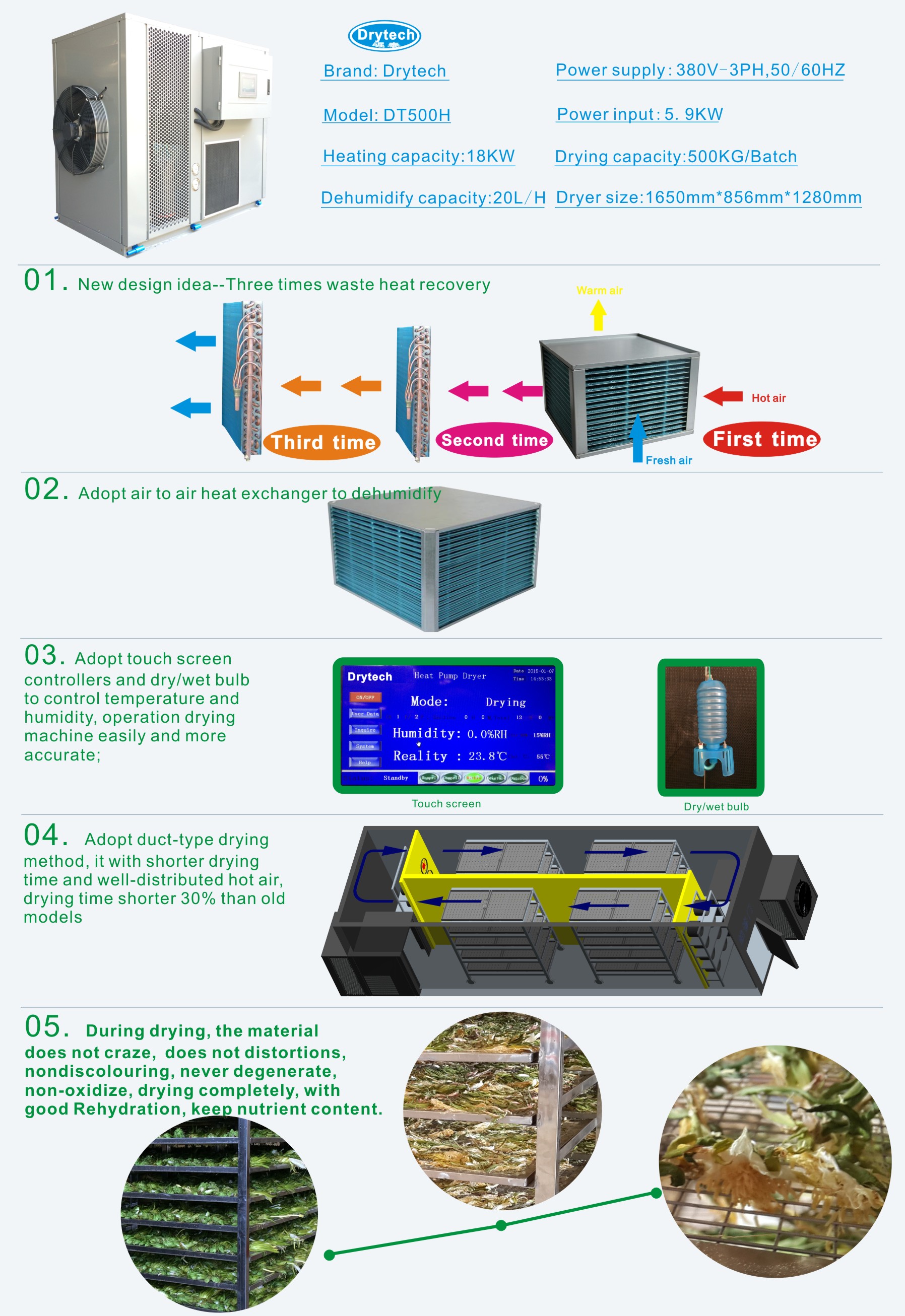

Drytech Heat Pump Dryer Features:

1. New design idea--Three times waste heat recovery;

2. Adopt heat regenerators to dehumidify;

3. Adopt touch screen controllers and dry/wet bulb to control temperature and humidity, operation drying machine easily and more accurate;

4. adopt duct-type drying method, it with shorter drying time and well-distributed hot air, drying time shorter 30% than old models;

5. during drying, the material does not craze,does not distortions, nondiscolouring, never degenerate, non-oxidize, drying completely, with good Rehydration, keep nutrient content.

Model | Power supply | Power input(KW) | Rated current (A) | Refrigerant (R134/KG) | Heating capacity(KW) | Cooling capacity(KW) | Dehumidify capacity(L/H) | Drying capacity (KG/batch) | Hot air flow(m³/H) | Dryer size(mm) | Drying chamber size(mm) | Warranty |

DT300H | 220V,1PH,50/60HZ | 4.3 | 25.0 | 2.5 | 12.0 | 8.0 | 12.0 | 400.0 | 15000 | 1650*856*1280 | 4500*2500*2200 | 2 Years |

380V,3PH,50/60HZ | 4.3 | 9.0 | 2.5 | 12.0 | 8.0 | 12.0 | 400.0 | 15000 | 1650*856*1280 | 4500*2500*2200 | ||

DT500H | 380V,3PH,50/60HZ | 5.9 | 13.0 | 3.8 | 18.0 | 12.5 | 20.0 | 500.0 | 15000 | 1650*856*1280 | 4500*2500*2200 | |

DT600H | 7.8 | 16.0 | 4.0 | 22.0 | 15.0 | 25.0 | 800.0 | 20000 | 1650*1056*1280 | 6000*2800*2200 | ||

DT1000H | 11.8 | 26.0 | 7.6 | 35.0 | 25.0 | 40.0 | 1000.0 | 20000 | 2089*1356*1590 | 6000*3000*2200 | ||

DT1200H | 14.6 | 32.0 | 8.0 | 44.0 | 30.0 | 50.0 | 1600.0 | 30000 | 2089*1356*1590 | 8000*3000*2200 | ||

DT300HD | 8.6 | 18.0 | 5.0 | 24.0 | 16.0 | 24.0 | 1000.0 | 30000 | 1650*856*1280 | 8000*2500*2200 | ||

DT500HD | 11.8 | 26.0 | 7.6 | 36.0 | 25.0 | 40.0 | 1500.0 | 30000 | 1650*856*1280 | 8000*2500*2200 | ||

DT600HD | 15.6 | 32.0 | 8.0 | 44.0 | 30.0 | 50.0 | 2000.0 | 40000 | 1650*1056*1280 | 10000*2800*2200 | ||

DT1000HD | 23.6 | 52.0 | 15.2 | 70.0 | 50.0 | 80.0 | 3000.0 | 40000 | 2089*1356*1590 | 10000*3000*2200 | ||

DT1200HD | 29.2 | 64.0 | 16.0 | 88.0 | 60.0 | 100.0 | 3500.0 | 60000 | 2089*1356*1590 | 12000*3000*2200 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

Model No.: DT300H

Power supply: 220V/380V, 50HZ

Power input: 5.5KW

Rated current: 25/9A

Heating capacity: 12KW

Cooling capacity: 8.0KW

Model No.: DT500H

Power supply: 380V,3PH,50/60HZ

Power input: 5.9KW

Rated current: 13A

Heating capacity: 18KW

Cooling capacity: 12.5KW

Model No.: DT600H

Power supply: 380V-3PH, 50/60HZ

Power input: 7.8KW

Rated current: 16A

Heating capacity: 22KW

Cooling capacity: 15KW