Drytech drying machine use for drying banana slice

Banana widely grown in tropical regions.

Banana is fragrant and nutritious. The plant is a large herb, emanating from the rhizome, and forming a false stem 3 to 6 meters (10 to 20 feet) high from the lower part of the leaf sheath; the leaves are oblong to oval, and some are long 3 to 3.5 meters (10 to 11.5 feet), 65 cm (26 inches) wide, with 10 to 20 clustered stem tops. The spike-like inflorescence is drooping, drawn from the top of the false stem, and the flowers are numerous, pale yellow; After the plant bears fruit, it dies, and the sucking roots that grow from the rhizome continue to reproduce, and each plant can live for many years. Native to Southeast Asia, it is cultivated in Taiwan, Hainan, Guangdong, Guangxi, etc.

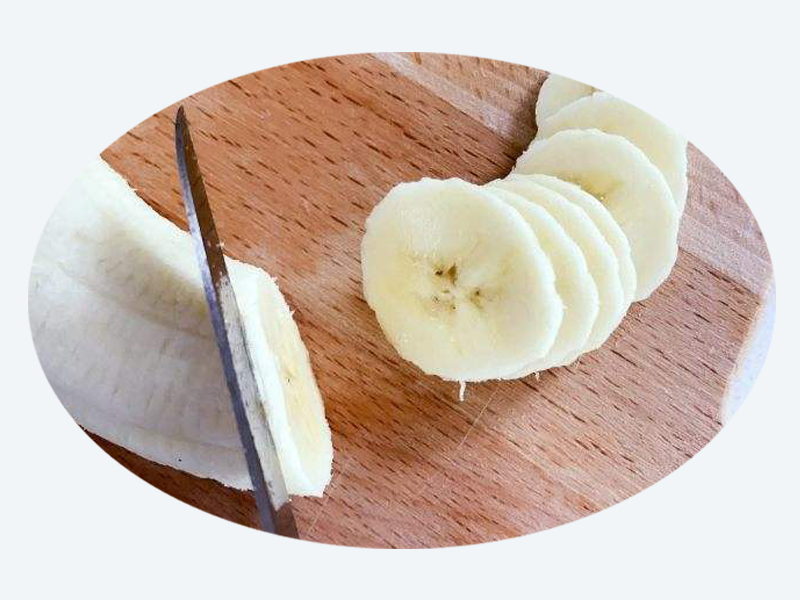

Banana processing steps

Dried bananas are dried bananas that are peeled and cut into pieces, which are easy to store and eat. Dried banana is what we often call banana chips, which is a very popular snack.

1. Raw materials and processing

The raw materials for processing dried bananas require a high degree of maturity, that is, to reach the edible maturity, the best time for color and aroma. Green bananas have poor flavor and astringency, and cannot be processed. Overripe bananas cannot be processed if they are in a soft and rotten state. For raw material processing, first pick out the rotten and diseased bananas and peel them by hand. The cutting method depends on the size of the individual bananas. If the individual is large, it should be semi-slitting.

2. Color protection treatment

Banana pulp contains polyphenols, even if it is a ripe banana, there are still polyphenols in the pulp, which will cause browning during processing and storage of finished products. In order to obtain products with good color and luster, it is necessary to carry out color protection treatment. Dip banana slices in lemon juice. This can improve the flavor and increase the vitamins, but the main purpose is to prevent the banana from turning brown

Bananas are rich in sugar. During the drying process, if the temperature is too high, for example, reaching 80 degrees Celsius, the phenomenon of sugar caramel will occur. If the temperature is too low, the baking time will be too long, neither of which meets the requirements. Therefore, the drying temperature should be controlled at 60 to 65 degrees Celsius, and the drying should be completed within 18 to 20 hours. The moisture content of the finished product is required to be 16%.

Call Us:

Call Us:  E-mail:

E-mail:

Address: Guangzhou City, Guangdong Province,P.R.China

Address: Guangzhou City, Guangdong Province,P.R.China

TEL: +86-159-8924-9151/Whatsapp

TEL: +86-159-8924-9151/Whatsapp

E-mail:

E-mail: