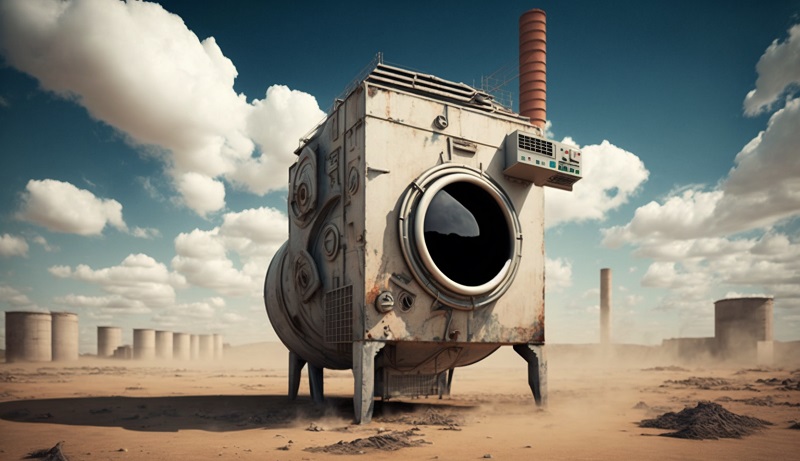

Heat Pump Dryers Replaces Traditional High-Energy, High-Pollution Equipment

Traditional industrial drying equipment often faces issues of high energy consumption and environmental pollution. With the constant advancement of technology, Drytech heat pump dryer(fruit drying machine, food drying machine, food dehydrator) technology has gradually gained recognition and application.

Compared to traditional drying equipment, heat pump dryer has many advantages.

Firstly, heat pump dryer can reduce energy consumption and also reduce the emission of harmful gases such as carbon dioxide, resulting in much less environmental impact.

Secondly, heat pump dryer can be used for low-temperature drying, preserving the original characteristics and quality of the materials, avoiding a series of issues caused by high-temperature drying. Additionally, heat pump dryer can regulate humidity, achieving efficient and rapid drying results.

The application of drytech heat pump dryers technology can not only meet the production needs of industry, but can also be widely used in daily life. For example, household appliances such as dryers and smart wardrobes can adopt heat pump dryer technology, achieving efficient, environmentally friendly, and safe drying results.

Despite the many advantages of heat pump dryer technology, there are still some issues with its promotion and application. Among them, high prices, high technical thresholds, and high equipment maintenance requirements are the main limiting factors for the promotion of heat pump dryer technology. However, with the continuous development of technology and the constant reduction of costs, we believe that heat pump dryer technology will gradually be widely applied in both industrial and household fields.

In summary, heat pump dryer technology replacing traditional high-energy, high-pollution equipment has become a development trend for the future. Drytech Heat pump dryer technology can not only reduce production costs and improve production efficiency, but also meets the requirements of environmental protection and sustainable development.

High-pollution and high-energy consumption drying equipment is usually applied in industries such as wood, paper, textiles, and others, where large amounts of moisture need to be evaporated from materials during the drying process. These devices use high-temperature, high-pressure, and high-speed processing to evaporate water and achieve the drying effect. However, this processing method not only consumes a large amount of energy, but also produces a large amount of waste gas, wastewater, and solid waste, seriously polluting the environment. The use of this high-pollution and high-energy consumption drying equipment not only increases production costs for enterprises, but also causes irreversible damage to the environment.

Call Us:

Call Us:  E-mail:

E-mail:

Address: Guangzhou City, Guangdong Province,P.R.China

Address: Guangzhou City, Guangdong Province,P.R.China

TEL: +86-159-8924-9151/Whatsapp

TEL: +86-159-8924-9151/Whatsapp

E-mail:

E-mail: